Results from Aquatraz in Eiterfjorden 2021

Salmon at 1,65 kg moved into an Aquatraz with a 13 meter lice skirt at SalmoNor’s location in Eiterfjorden on Feb 2nd 2021. Production in Aquatraz (AQT) was compared with a conventional control cage (KTR) with lice skirt and a Midt-Norsk ring, at the same location. The salmon was slaughtered in September 2021.

The results in the table shows that compared to the control cage, Aquatraz achieved :

- lower total production cost (incl depreciations)

- higher sales price

- larger margin of profit

- no delousing (five in KTR)

- lowered mortality rate

The depreciation period is 15 years for AQT and 5 years for KTR, with no residual value, and an interest rate of 3,15%.

Production costs in the control cage was calibrated to NOK 38,78, which corresponds to the average production costs in Trøndelag for 2019. AQT is calibrated with the same total.

Salmon price from all of 2019 (Nasdaq Salmon Index) was used in the analysis

| Aquatraz (AQT) | Control (KTR) | Difference | |

|---|---|---|---|

| Prod.cost, incl depreciation | 36,37 NOK/kg | 38,78 NOK/kg | -2,31 NOK/kg |

| Price | 56,39 NOK/kg | 54,65 NOK/kg | 1,74 NOK/kg |

| Margin of profit | 19,92 NOK/kg | 15,87 NOK/kg | 4,05 NOK/kg |

| Weight (round) | 5,36 kg | 4,83 kg | 0,53 kg |

| Max density | 17,3 kg/m3 | 17,7 kg/m3 | -0,4 kg/m3 |

| Delousing | None | 5 rounds | -5 rounds |

| Mortality | 2,08 % | 10,97 % | -8,89 % |

Analysis from production in an Aquatraz in Eiterfjorden 2021, Norwegian

Unfortunately these reports only exist in Norwegian language. Please, contact us, if you would like more information than the summary presented here.

More results from Aquatraz

The production analysis from Midt-Norsk Havbruk’s site in Eiterfjorden 2021 is the first analysis from a production cycle that was not included in the development project itself. The latest results presented above are therefore not surprisingly, the best results of the productions analysed so far. We expect that the results will continue to improve as knowledge of the cage increases, and more optimal production models are utilised.

As part of the development program, production in each new generation has been analysed and documented for the Norwegian Directorate of Fisheries. The final reports for the biology programs for Aquatraz G2 and G3 are linked here. These reports also contain more in-depth analyses of fish health, water quality and product quality. Despite the fact that the production analyses have been carried out in new technology, Aquatraz has shown good results, also in the previous production cycles.

Production costs have generally been lower in Aquatraz than in the control cages. The main reason for this is that Aquatraz effectively protects against salmon lice.

Evaluating succsess for Aquatraz development project

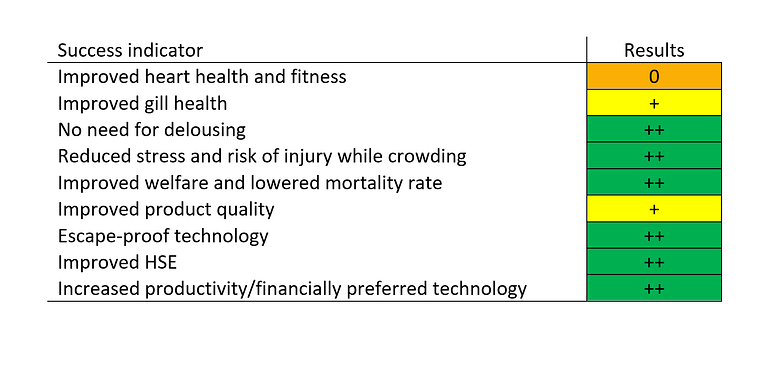

The Success indicator figure from the final report shows the internal success criteria set at project start, and evaluation of these after completion of the development project. See Figures 2 and 3 which show results and measurement scale. In sum, the results are considered very good with a full score on criteria such as:

- no delousing

- lowered stress

- improved welfare and mortality rate

- escape proof technology

- HSE

- increased productivity /financially preferred technology

Due to the deeper water intake in Aquatraz compared to conventional cages, a lower plancton concentration was expected, which could have a positive effect on gill health. The biology programs show tendencies towards improved gill health in Aquatraz. The effect was most pronounced with the deepest lice skirt of 18 meter. Visual observations also showed clearer water inside the Aquatraz cage, than outside, as seen in the picture below from Aquatraz in Årsetfjorden, June 2021.

For product quality, there were several registrations of improved muscle quality and colouring in fish from the Aquatraz cages, but the findings did not point unequivocally and systematically in the same direction across all the biology programs.

No improvement was detected from the test samples regarding heart health and fitness. At the time of the application in early 2016, it was known from experiments that excersising salmon in the freshwater phase had positive effects. With Aquatraz in operation in the fjord, as opposed to in controlled experiments, the water speed varies internally in the cage and throughout the day. There are clear observations of the salmon seeking out the area behind the flow setters, where the water flow reach maximum speed. But it was not possible to select these specific individuals for testing.

Project management

The Aquatraz project was funded and led by project sponsor Midt-Norsk Havbruk. The technology development of Aquatraz was led by Seafarming Systems, while the follow-up of the biology programs were led by Aqua Kompetanse. The permanent project team consisted of few people working closely together throughout the project. The communication between the operating organization and the project worked well. Experiences and challenges in operation have been communicated unfiltered from employees on the edge of the cage to the project, ensuring that changes and improvements could quickly be implemented in the next generation, and improved on existing cages. The project’s significant technical development and knowledge production can largely be attributed to the close collaboration between the operating and project organization. Good cooperation between developer and end-user is essential for successfull development of new technology.

Thanks to a small but competent project organization, and the delegation of responsibility and authority from project sponsor to project management, the implementation of the Aquatraz project has gone faster than what was envisioned during the application process.

Energy consumption for salmon production

The Aquatraz semi closed salmon cage use an effeicient method for water exchange. The method used in the three fist generation Aquatraz cages requires a mere 0,1 to 0,2 kWh per kg salmon produced. Figure 4 shows energy consumption divided by industry sector, and energy needed to produce 5 mill tonnes salmon per year in Aquatraz, compared to in different types of closed fish farming technologies. If 5 mill tonnes salmon were to be produced in Aquatraz cages, the total energy expenditure would be 5 TWh. That is only 1/15th of the energy required in floating closed cages.

The fourth and last generation in the development project tested a new patent-pending water exchange method. This method is expected to further lower the energy consumption, and potentially leading to the Aquatraz beeing a net electricity producer.

„

Seafarming Systems would like to thank Midt-Norsk Havbruk (now SalmoNor) and all participants who have contributed to the Aquatraz development project being a great success.

We look forward to keep developing Aquatraz further together with SalmoNor and other Norwegian farmers, as well as our other partners on technology and biology.

”